Title: Multistage Micro-Turbine Generator

Filed: 25/10/2011

Number: GB1118443.9

This invention relates to âexhaust gas turbochargers for motor vehiclesâ, âauxiliary power unit (APU) for aircraftâ, âelectrically driven superchargerâ and âhybrid turbochargerâ

This invention extends âDecoupled Gas Turbine Generatorâ (GB2477548).

It is well known to provide a centrifugal compressor such as is used in turbochargers, and some superchargers, and aircraft auxiliary power units (APU).

It is also well known to provide a centrifugal turbine such as is used in turbochargers and aircraft APUs.

It is also well known to employ a combustion chamber to provide for the mixing of fuel-air and burning to produce kinetic energy.

It is also well known to use an electric motor to power a centrifugal compressor as in an electric supercharger or hybrid turbine or at lower pressure in a garden leaf blower.

It is also well known to use a generator powered by a turbine in a hybrid turbocharger also a wind turbine.

It is well known to use a heat exchanger in a turbine engine to improve the efficiency of the engine (Chrysler Turbine Car).

The invention seeks to provide a viable micro-turbine system for use in vehicles.

According to the present invention there is provided a multistage micro-turbine generator comprising:

a) a low pressure compressor,

b) a heat exchanger,

c) a high pressure compressor,

d) a combustion chamber,

e) a high pressure turbine,

f) a low pressure turbine.

Preferably the compressors and turbines are of the centrifugal type.

Preferably the high pressure compressor and high pressure turbine are connected to the combustion chamber at opposite ends of the chamber.

Preferably the low

pressure compressor and turbine are more than twice the size of the

high pressure compressor and turbine respectively.

Preferably

the high pressure compressor and turbine are of similar

size.

Preferably the low pressure compressor and turbine are

of similar size.

Preferably the compressor's fans are

connected directly to the shaft of the motors.

Preferably the

turbine's fans are connected directly to the shaft of the

generators.

The invention also relates to a method of

producing electricity from a combustible liquid or gas.

Preferably

the fuel used in the combustion chamber is hydrogen, gasoline or

propane.

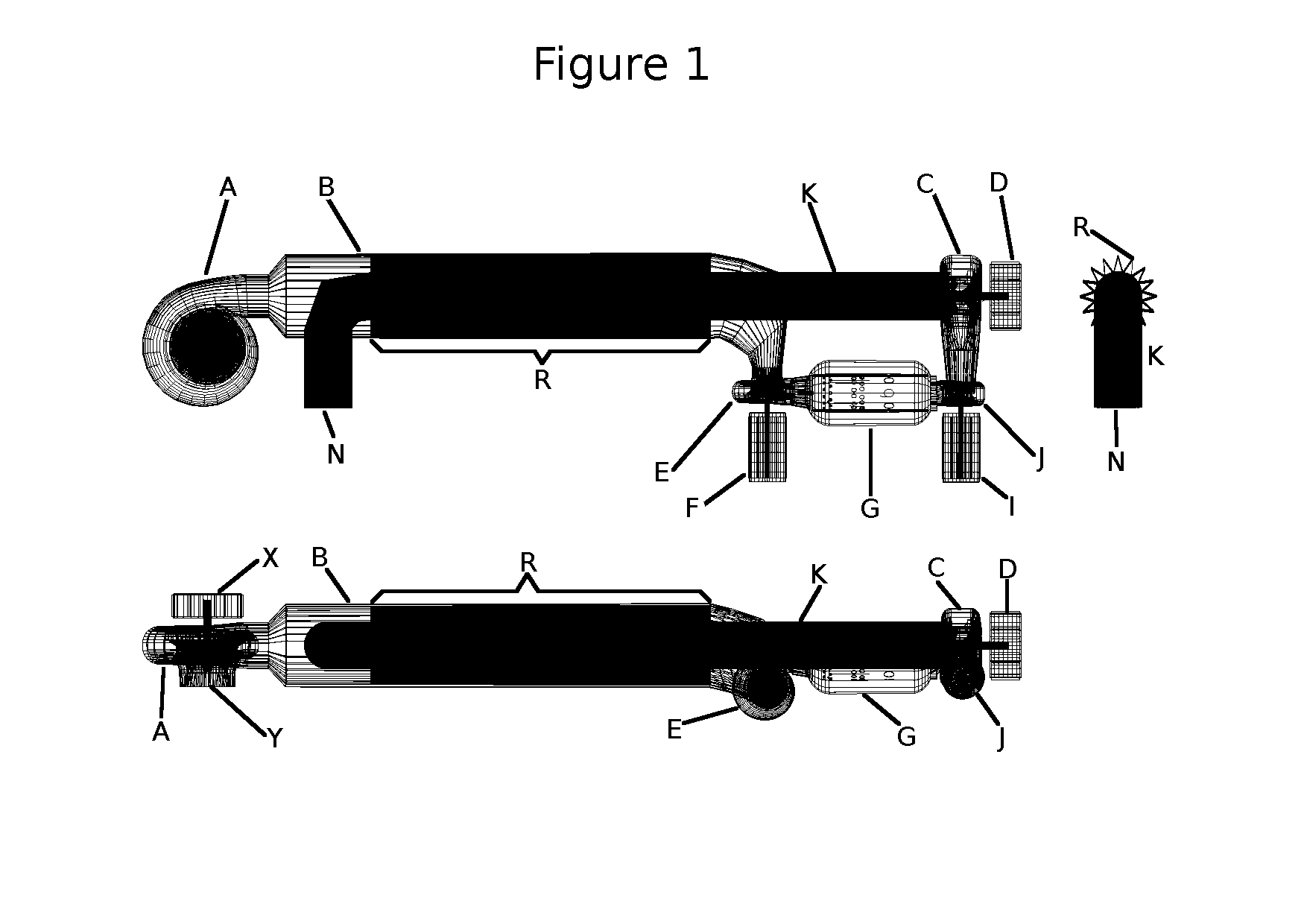

An embodiment of the invention will now be described with reference to figures 1 and 2 of the accompanying drawings.

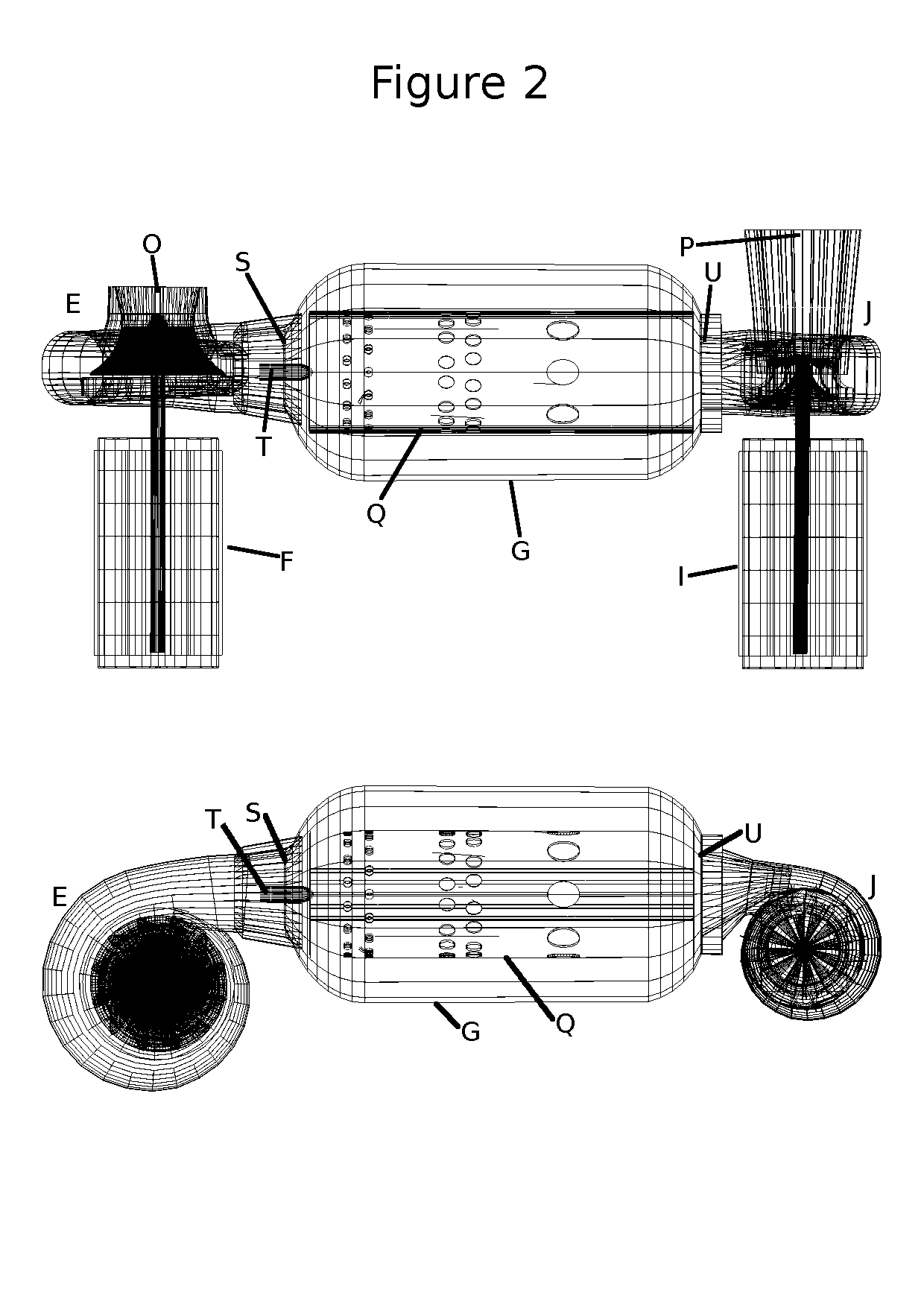

Figure 2 shows parts E, F, G, H and I or figure 1 in more detail.

Air is drawn into the engine via low pressure compressor A, preferably at the front of the vehicle.

Low pressure compressor A is powered by electric motor X.

The air is compressed to approximately 3:1 (or preferably higher) and sent through the heat exchanger B.

Heat exchanger B has 2 main components: the outer case for the incoming air and an inner hot pipe K which is for the hot exhaust.

Around the inner hot pipe K is fitted a heat-sink R which aids the transfer of heat from the hot exhaust gas to the incoming cooler air.

The air is heated in the heat exchanger B and then passes to the high pressure compressor E.

High pressure compressor E is powered by a high speed electric motor F.

The heat exchanger also increases the pressure of the air by thermal expansion.

This then compresses the air a further 3:1 (or preferably higher) to produce a full pressure of approximately 10 atmospheres, or greater.

The compressed heated air passes to combustor G where it is mixed with fuel and burned in combustion chamber Q.

The combustion increases the pressure and temperature of the gas mix as it passes through combustion chamber Q in combustor G.

This hot high pressure gas passes through the high pressure turbine J.

The high pressure turbine J removes kinetic energy from the hot high pressure gas which powers the high speed generator I.

The hot lower pressure gas passes through the low pressure turbine C which extracts more kinetic energy to power generator D.

The hot low pressure gas passes back through the heat exchanger B via the hot pipe K.

This passes heat energy to the incoming cool air via heat-sink R.

Finally the cooled low pressure gas is ejected via exhaust N, which would preferably be piped to the rear of the vehicle similar to a current piston engined vehicle.

This pressure is maintained for the full power range since the compressors are electrically driven and are independent of the speed of the turbines or the power drawn from the generators.

To change the power of the engine one would vary the fuel fed into the engine and balance it with the power drawn from the generators to maintain the combustion pressure and thus the efficiency.

This would mean the engine would operate closer to the idealised Brayton Cycle for most of it's output range.

If the engine maintained 10 atmospheres output from the compressors the Brayton Cycle shows an efficiency of 50%, compared to piston engine cycles of 37%.

If the engine is made using ceramic materials, which are being researched today, the pressure and temperature could be increased considerably and efficiencies of 70% would be possible.

Preferably, the complete system would be controlled by a intelligent management unit (similar to an ECU) to maintain maximum efficiency.

The high speed motors and generators would preferably be the âBrushless Motor without Permanent Magnetsâ (GB2477547) due to the light weight rotor needed for high speed operation.

1.

A multistage micro-turbine generator comprising:

a) a multistage

centrifugal compressor,

b) a heat exchanger,

c)

a combustion chamber,

d) a multistage centrifugal turbine.

2. A multistage micro-turbine generator according to above claims, where the centrifugal compressors are powered independently by electric motors.

3. A multistage micro-turbine generator as above claims, where the gas between compressors stages is preheated in a heat exchanger or other heating device.

4. A multistage micro-turbine generator as above claims, where the turbines independently power generators.

5. A multistage micro-turbine generator substantially as hereinbefore described with reference to and as shown in the accompanying drawings.

6. A method of generating electric power using multiple decoupled compressors and turbines substantially as hereinbefore described.

The invention relates to a gas turbine engine.

The invention is a method of producing electric power from a combustible liquid or gas.

Normally in a gas turbine engine a compressor fan or fans are powered directly from a turbine fan or fans in the same engine via a connecting shaft.

These may all be on the same shaft or on separate concentric shafts where compressor fan sets are paired with turbine fan sets.

In this invention the compressors are powered by electric motors, which are powered indirectly from generators on turbines in the same engine.

The pressure in the engine is maintained at all output levels by independently controlling the compressors and turbines to ensure maximum efficiency.

This maintains the efficiency of the micro-turbine system and makes it appropriate for use in vehicles.